Product Description

Surface Mount Inductive Loop

The Surface Mount is ideal for installation on post tension concrete where it may not be possible to cut the surface for a conventional loop due to reinforcement or water membrane damage. Thus offering a reliable, cost-effective alternative to other methods of vehicle detection.

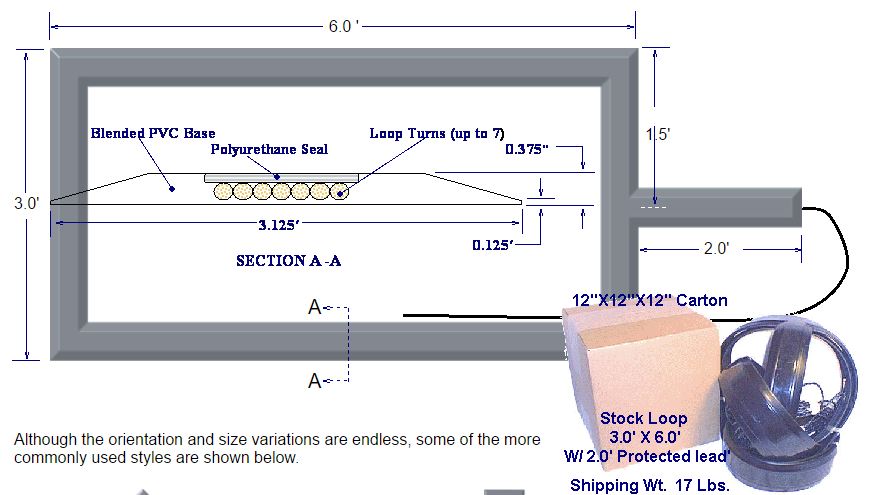

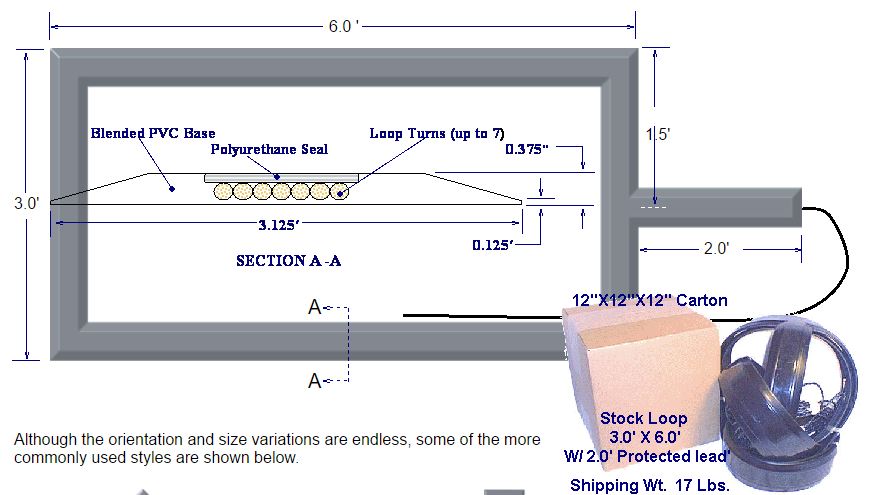

The loop is manufactured with two materials carefully selected to absorb impact and protect the loop wires. The profile of the loop has been designed with a main body thickness of only 0.375” and leading and trailing edges of only 0.125”. This low profile reduces tire noise and impact on steering and vehicle suspension at higher speeds.

The base section is extruded in blended PVC with an upper surface wire sealant of polyurethane. The two compounds were selected for their strength and ability to allow the compatible movement of all the materials involved.

Extrusion Dimensions:

Width: 3.125” Thickness 0.375” to 0.125” at the edges

Standard Lead-in: All loops are constructed with 18’ of lead-in unless otherwise specified. (Custom lead Length, Gauge & Jacket available)

Loop Wire: 14GA THHN PVC with nylon jacket, Resistant to oils, water, acids, ozone, alkaline, and abrasion.

Operating Inductance Range :20 to 1500 µh

Operating Temperature: -104° F ~ +400 ° F.

Sizes & configurations

The stock Surface Mount Loop show below is available for immediate shipment. (most of the time) Other sizes, orientations and large quantities require a 30 to 60 day lead time from Purchase Order date.

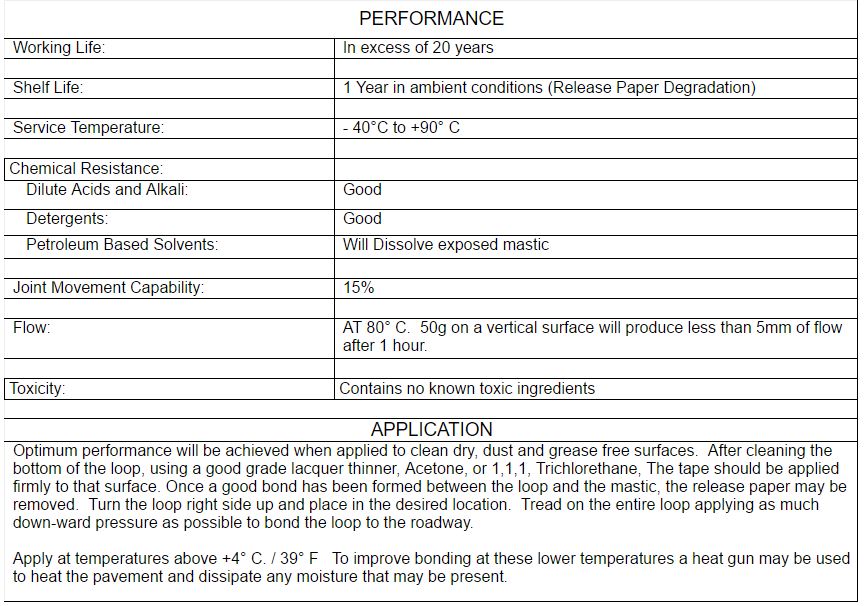

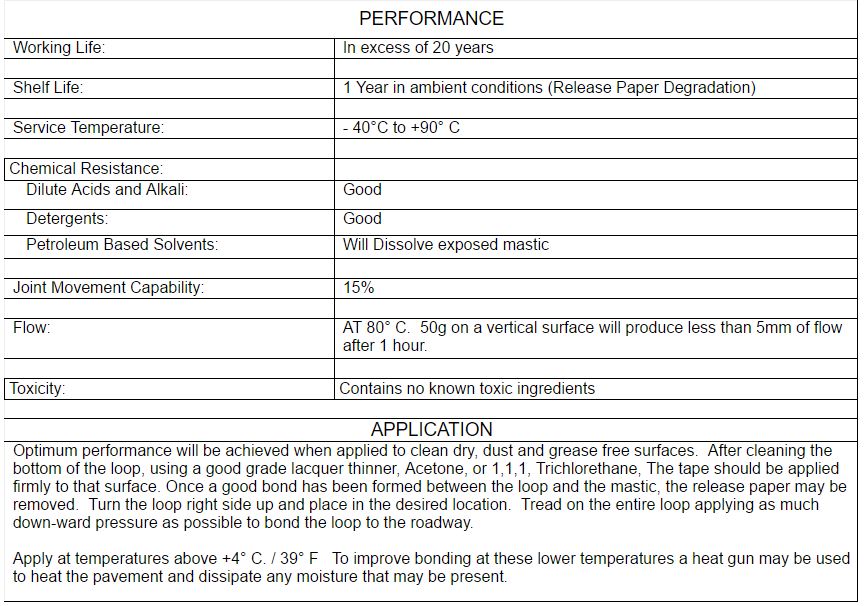

Surface Mount Loop Adhesive

Instructions for the permanent bonding for the S-LS Series Inductive Loop

Surface Mount Inductive Loop, Installation Tips, Page 5

NAME & PART #:

LOOP ADHESIVE, AD-P 300

100% SOLIDS

MANUFACTURER:

Dynamis, Inc.

415 East Venice Avenue

Venice, Florida 34292

PRODUCT DESCRIPTION

Loop Adhesive ADP-300 is a two component, 1:1 mix (by volume), polymer adhesive for the bonding of surface mount inductive loops. Loop Adhesive ADP-300 is a 100% solids, semi-rigid compound with excellent resistance to gasoline, diesel fuel, greases, oils, anti-freeze and other chemicals commonly encountered in parking garages and parking areas.

LIMITATIONS

Concrete surfaces should be (A) not less than 36°F, (B) clean and dry and (C) structurally sound. Best results and faster cure times are achieved when surface temperatures are 65° F or higher.

COLOR: Black

PACKAGING: 1/2 Gal. Units 1-Quart Component A in a 1 Gallon Can

1-Quart Component B in a 1 Quart Can

INSTALLATION

Areas to receive Loop Adhesive ADP-300 should be prepared as follows:

1. All grease and oil must be removed from surface by scraping. Use wire brush for heavy acum-

ulations. This must be followed by a thorough solvent wiping with either a good grade lacquer

thinner, Acetone, or 1,1,1, Trichlorethane. The same solvents and clean white cotton rags must

be used to wipe the bottom (side to be bonded) of the loop approximately 10 minutes prior to

application.

2. After grease removal, area should be ground with electric grinder and suitable concrete grinding

stone or wheel, and then thoroughly air blown or vacuumed to remove all dirt and dust.

3. Any deteriorated or damaged concrete should be repaired with EPO Patch, epoxy concrete

patching material, prior to bonding loop strips.

4. Exact area to which adhesive is to be applied should be outlined with masking tape.

5. Adhesive should be mixed by pouring contents of quart can (Component B) into gallon can (Component A), Stir thoroughly, taking care to scrape sides and bottom of containers. Mix until uniform color and consistency is achieved. Apply to area outlined by tape, approximately 1/8″ thick.

6. Press loop strips gently into adhesive, allowing adhesive to creep up over loop edges. (Note: Loop strips should be uncoiled and allowed to flatten out prior to bonding).

7. After strip placement in adhesive, strips should be uniformly weighted to insure total contact with adhesive. Metal bars, approximately 2′ Long x 1″ x 1″, are ideal for this purpose.

8. Approximately 15 to 20 minutes will be available for adhesive mixing and placement. All surface preparations should be done prior to mixing.

9. Tape should be stripped as soon as adhesive begins to gel on surface.

10. Adhesive will set hard and be ready for traffic in approximately 2 to 3 hours at surface temperatures of approximately 65ºF to 75ºF. Higher surface temperatures will accelerate cure time and lower surface temperatures will slow down cure time.

11. All clean up of tools and equipment must be accomplished with solvent prior to cure.

12. If loop strip is to span an existing expansion joint, loop should not be bonded over joint.

PRECAUTIONS

Loop Adhesive ADP-300 is not flammable; however, the cleaning solvent is. Keep solvent away from heat, open flame and pilot lights. Avoid prolonged contact with skin and breathing of vapor or mist from either adhesive or solvent. Use both with adequate ventilation. Keep solvent and adhesive out of reach of children.

GUARANTEE

The manufacturer warrants that the material meets specifications listed and limits any warranty to the replacement of material only.

Adhesive Mastic

Product Specifications & Application